Here is a little bit of the fab work I have had done just to make this car come together. As we all know nothing ever fits when you start mixing brands and parts not desinged together around.

Here is my 1995 Cobra with a full MM suspension, Dart 348ci 4.125" motor, AFR185 heads, Ed Curtis grind, Viper spec'd T56, Precission 76mm turbo and a BG Customs kit, full AEM ECM and EPM (coil on plugs), and the list goes on.

I will post up some pics and explain why I went the route I did. The main goal for the car was to kepe the stock hood and outward appearance. So a lot of work went into that point alone.

Photobucket is slow so I will start here:

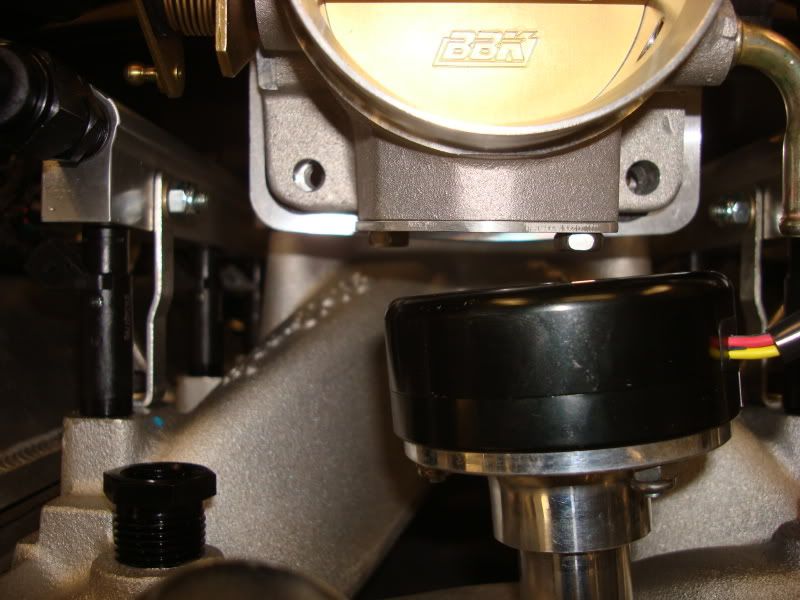

Edelbrock Super Victor manifold - no rear water jacket and I wanted to feed heater core from the back of the block. So result was, weld (2) -8an bungs to the manifold bosses and drill straight through. I used 1/2" fuel line with -8 tube nuts and sleeves to build the crossover and a T in the middle to feed the heater core off of. Oh no hose clamps allowed on the car. All -an fittings only.

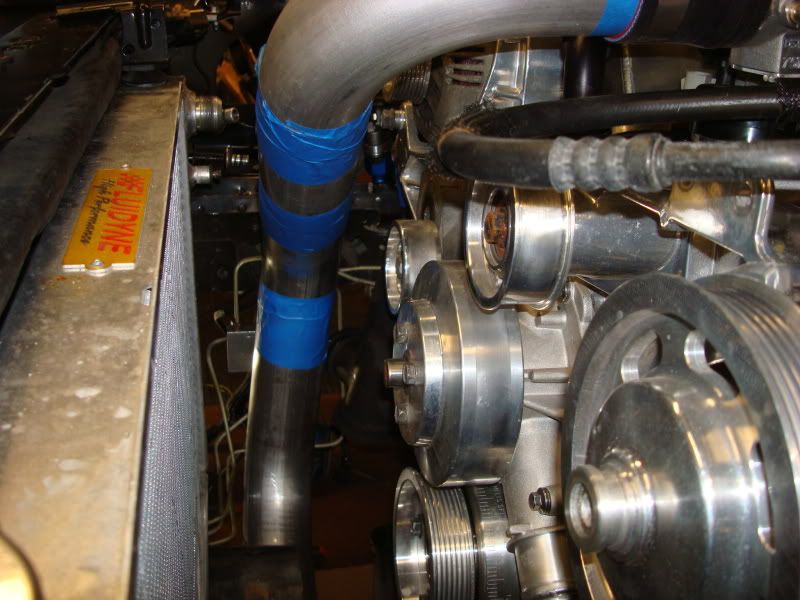

A dry run when I thought I was gonna tap that bung. Sure glad I came to my senses and welded a bung to it.

Here is my 1995 Cobra with a full MM suspension, Dart 348ci 4.125" motor, AFR185 heads, Ed Curtis grind, Viper spec'd T56, Precission 76mm turbo and a BG Customs kit, full AEM ECM and EPM (coil on plugs), and the list goes on.

I will post up some pics and explain why I went the route I did. The main goal for the car was to kepe the stock hood and outward appearance. So a lot of work went into that point alone.

Photobucket is slow so I will start here:

Edelbrock Super Victor manifold - no rear water jacket and I wanted to feed heater core from the back of the block. So result was, weld (2) -8an bungs to the manifold bosses and drill straight through. I used 1/2" fuel line with -8 tube nuts and sleeves to build the crossover and a T in the middle to feed the heater core off of. Oh no hose clamps allowed on the car. All -an fittings only.

A dry run when I thought I was gonna tap that bung. Sure glad I came to my senses and welded a bung to it.

Comment