Originally posted by CJ

View Post

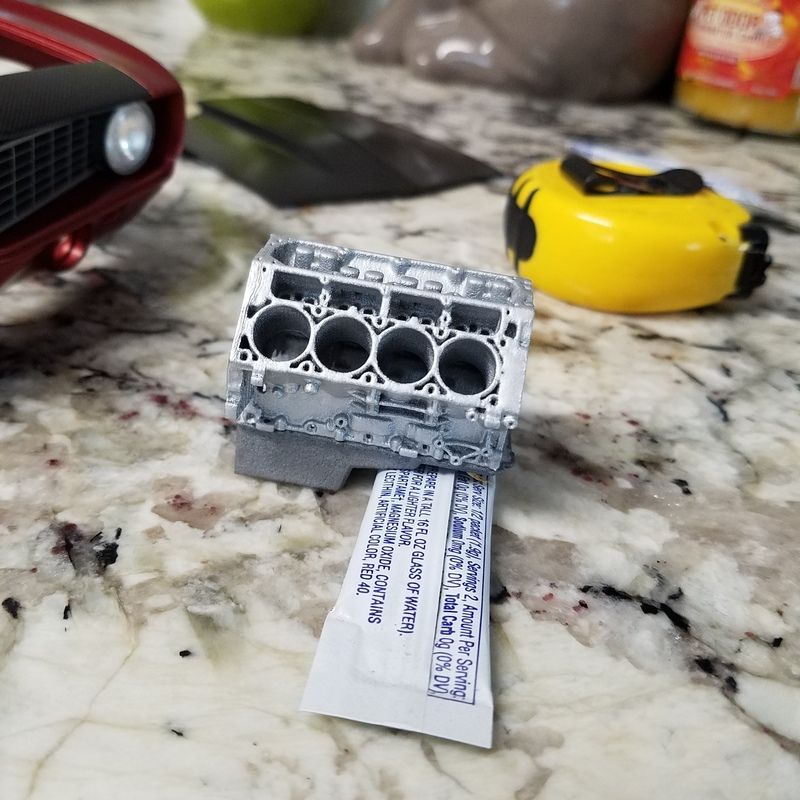

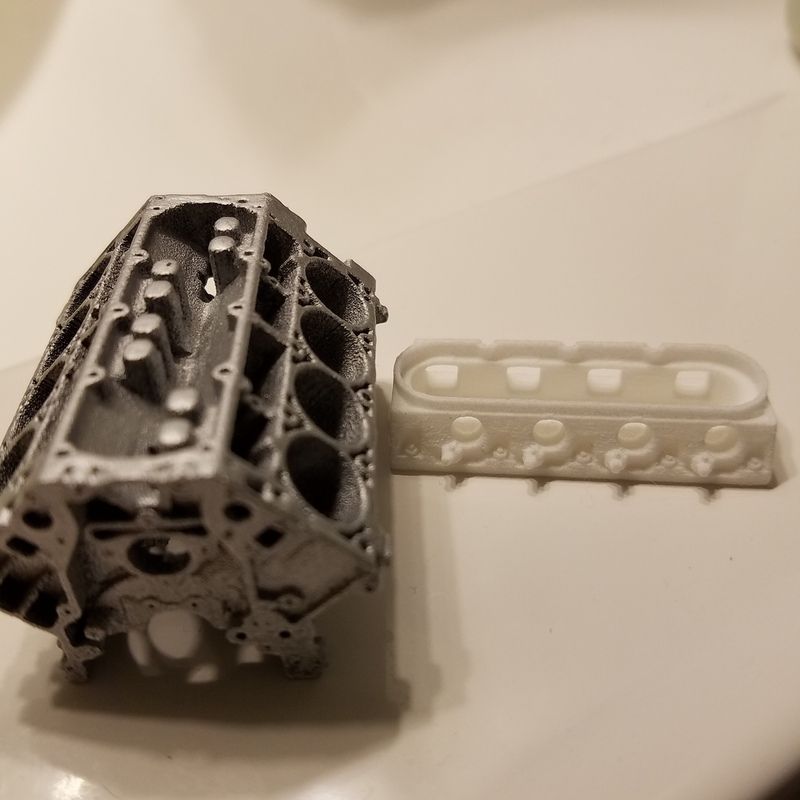

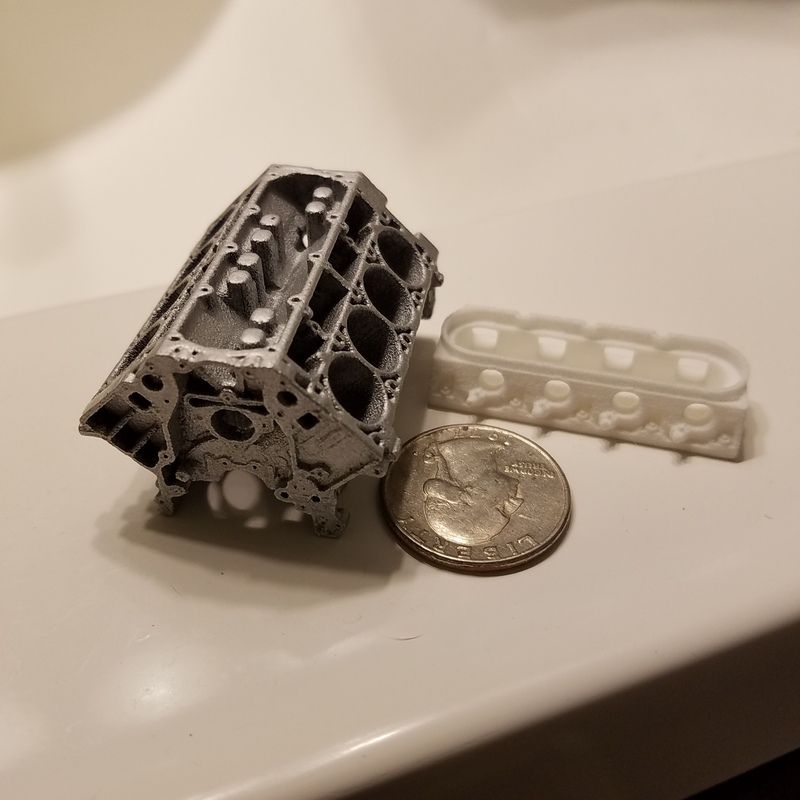

Some of the more rough parts, I ordered that way intentionally to retain the cast/textured look. I think I am going to go at the whipple with a fine grit paper and smooth out a few areas of it.

I'm trying to convince myself that reducing the amount of detail is in my best interest to get this thing finished. Trying to be realistic about what is going to be seen when it is in the engine bay with all of the other details. Do I need this bolt, or that bolt, will the texture be seen? If it is seen will it be noticeable and if so, how out of scale or unrealistic is it?

After this thing is done I've got 3 1/12th scale Mustangs, a 1/12th scale S-10, and a truck load of 1/24-25th scale stuff that is all mid project.

Leave a comment: