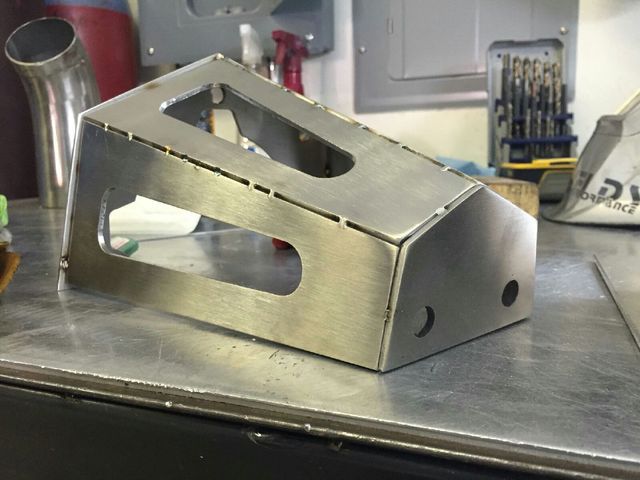

First thing made was the sheet metal elbow. Wanted to keep as much piping out of the engine bay as possible to keep it looking as clean as possible so we went with a rear facing TB and under dash mounted Air to water IC. We make everything in house as well.

Had a good friend who does powder coating ceramic coat the headers and exhaust housings. He also did the intake, elbow, A-arms and several other things. He will be the one doing all the powder coating for the car. Coating by Coates in Houston or Scott Coates on Facebook if you need anything coated he is a bad ass and reasonably priced also.

Had a good friend who does powder coating ceramic coat the headers and exhaust housings. He also did the intake, elbow, A-arms and several other things. He will be the one doing all the powder coating for the car. Coating by Coates in Houston or Scott Coates on Facebook if you need anything coated he is a bad ass and reasonably priced also.

Comment