Shoulda posted here, anybody proficient?

Announcement

Collapse

No announcement yet.

Solidworks

Collapse

X

-

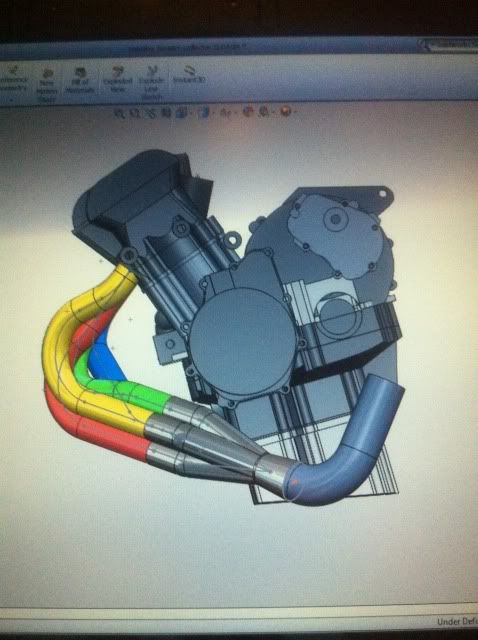

we went from this

to this

we are slow with the program, but this was our first attempt at prototyping a header without starting from scratch with raw materials. actual header construction took under 3 hours after we sent the file to the bender and spit out all of the tubes and bends............pinto gt with wood trim

Comment

-

That looks pretty good. How are you having it welded? EB? I'm assuming that is an equal length header? What version of solidworks are you using? Looks like you're using a spline to obtain the correct geometry? I don't know much about the specifics of exhaust gas pulse theory but your bend radius' look good. Whats the RPM on that motor? I'm just hypothesizing so I might be wrong but I would think max RPM, static and dynamic pressure and engine volume should give a reasonable expectation of tube length. Either way looks like a cool project. Wish you the best of luck!2012 mustang gt. 3.31 MT

Comment

-

I think it's solidworks 10, dont get me lying, i have no clue, i think i remember hearing my buddy that drew this use the word spline, but i'm sure there are tons of shortcuts compared to how we did this(weldments and extrusions). A lot of variables are fixed when we start design. We know the center line length of the tubes we want, and the bend radius is fixed because of the bend dies we own for our bending equipment and the thin wall tubing. When you start a header out of raw material you might spend 3 days getting to the last tube, which ends up being an 1" too long or too short. This way the collector location was dictated by the lengths of the tubes and that we want the firing order in a circular pattern into a 4-1 collector. this header ended up with each tube within a 1/4" of length after measuring by volume.........Originally posted by Jasonone View PostThat looks pretty good. How are you having it welded? EB? I'm assuming that is an equal length header? What version of solidworks are you using? Looks like you're using a spline to obtain the correct geometry? I don't know much about the specifics of exhaust gas pulse theory but your bend radius' look good. Whats the RPM on that motor? I'm just hypothesizing so I might be wrong but I would think max RPM, static and dynamic pressure and engine volume should give a reasonable expectation of tube length. Either way looks like a cool project. Wish you the best of luck!pinto gt with wood trim

Comment

-

Computer aided design makes things so much easier. Your header looks like something one would buy from kooks or somethin so congrats on that. Seems like you have a handle on things. How much power is that mill putting out?2012 mustang gt. 3.31 MT

Comment

-

If you're really getting amibitious and want to turn this into a production line there should be some shops in the metroplex that do EB welding. The eb welding machine should be compatible with solidworks or mastercam (or something simliar) and should also be capable of compensating for weld thickness and such. Just FYI. Mastercam is the program that converts solidworks part files into machine code. For a history lesson all machining was done by handles and feeds until the 70's or so when CAD, CAM and CNC came around. CAD computer aided design, CAM computer aided machine, CNC computer numerically controlled. I'm sure they have auto tube benders as well, if you want to go that route. Tons of stuff out there. You could even have the tubes wire EDM'ed apart, and rewelded if you're unsatisfied with the +- 1/4" tolerance. Tons of fun stuff you could do but I tend to get carried away...2012 mustang gt. 3.31 MT

Comment

-

we have been building headers for a LONG time, this is just the first step to making it easier to prototype. Kooks is one of our competitors in the cup, busch, and truck stuff. this is all tig'd, stainless, titanium, or inconel. our bender is a CNC bender, not sure what the software is called though. this particular piece is for a 600cc engine that makes in the 115-125 hp rangepinto gt with wood trim

Comment

Comment