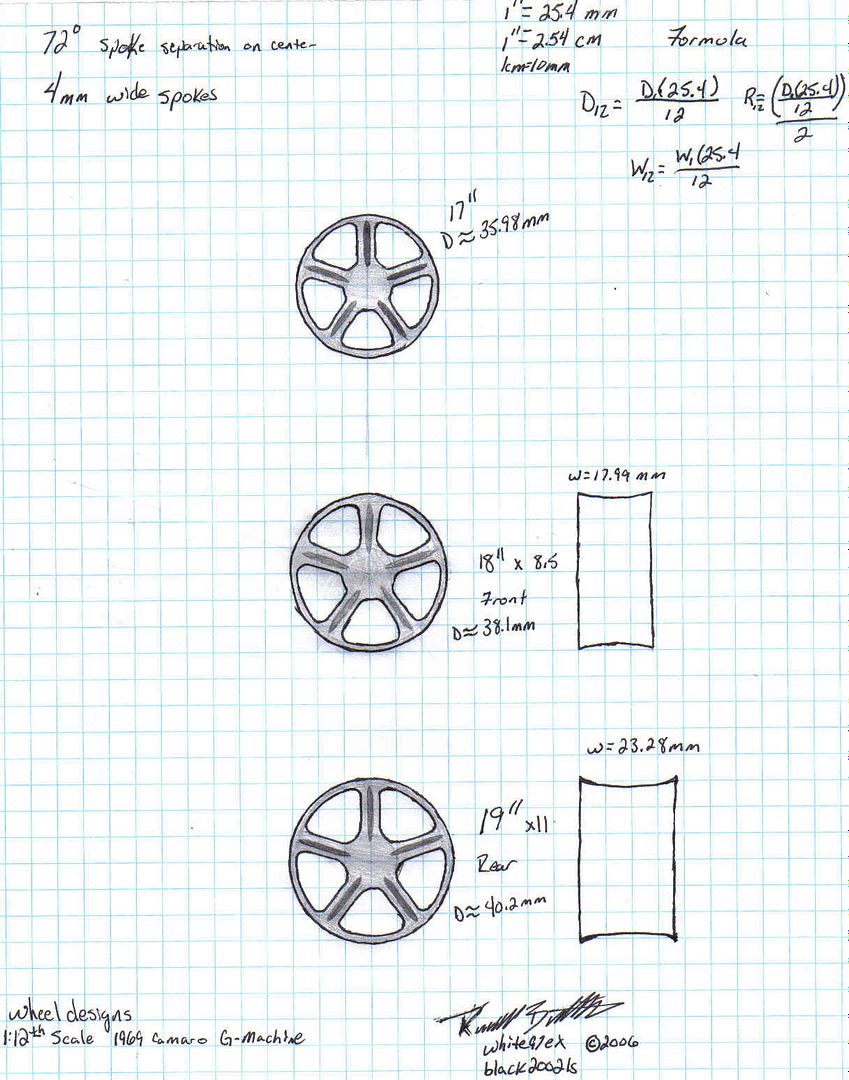

Here is what I'm wanting for the Camaro

if it could be done in two pieces that would be awesome. If I need to create the center piece, no big deal. I'll do a little research this weekend, and talk to some of the guys running these wheels on the camaro and see what the back spacing and measurements are. I'll have to pull out the model to see what will actually fit in the rear with the current axle length and estimate that because the brakes aren't done yet....

if it could be done in two pieces that would be awesome. If I need to create the center piece, no big deal. I'll do a little research this weekend, and talk to some of the guys running these wheels on the camaro and see what the back spacing and measurements are. I'll have to pull out the model to see what will actually fit in the rear with the current axle length and estimate that because the brakes aren't done yet....

Comment