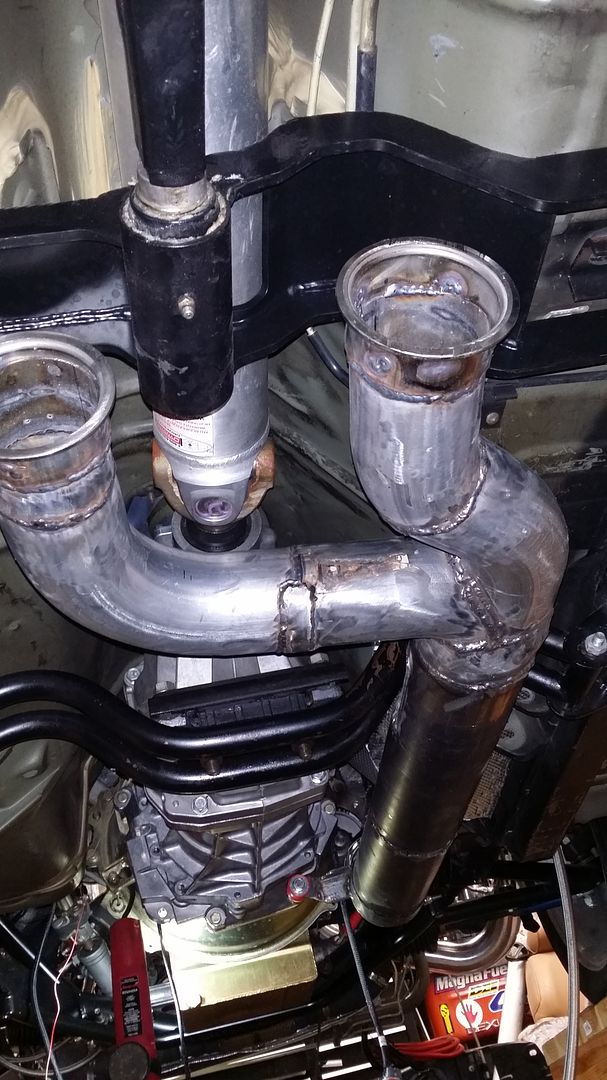

Got the exhaust built all the way to the v-band flange before it transitions to aluminum. The flanges on the end have enough slack in the inside that I can tilt them to get the final angle straight.

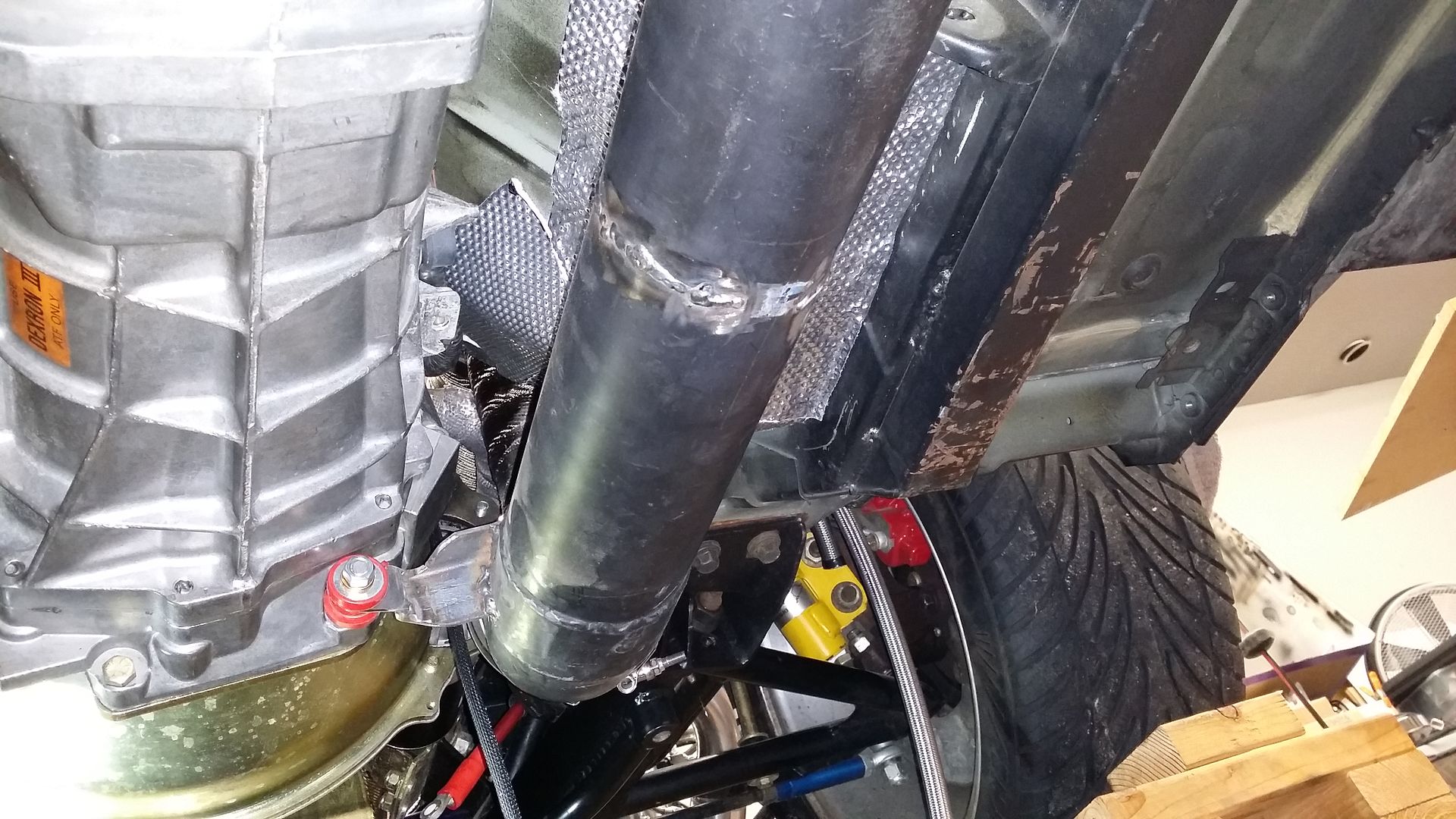

Had too big of a gap here so had to put a patch in.

Welds getting more rthym.

Had too big of a gap here so had to put a patch in.

Welds getting more rthym.

Comment